Metallic Copper as an Antimicrobial Surface▿

This article has been

cited by other articles in PMC.

ABSTRACT

Bacteria, yeasts, and viruses are rapidly killed on metallic copper surfaces, and the term “contact killing” has been coined for this process. While the phenomenon was already known in ancient times, it is currently receiving renewed attention. This is due to the potential use of copper as an antibacterial material in health care settings. Contact killing was observed to take place at a rate of at least 7 to 8 logs per hour, and no live microorganisms were generally recovered from copper surfaces after prolonged incubation. The antimicrobial activity of copper and copper alloys is now well established, and copper has recently been registered at the U.S. Environmental Protection Agency as the first solid antimicrobial material. In several clinical studies, copper has been evaluated for use on touch surfaces, such as door handles, bathroom fixtures, or bed rails, in attempts to curb nosocomial infections. In connection to these new applications of copper, it is important to understand the mechanism of contact killing since it may bear on central issues, such as the possibility of the emergence and spread of resistant organisms, cleaning procedures, and questions of material and object engineering. Recent work has shed light on mechanistic aspects of contact killing. These findings will be reviewed here and juxtaposed with the toxicity mechanisms of ionic copper. The merit of copper as a hygienic material in hospitals and related settings will also be discussed.

The use of copper by human civilizations dates back to between the 5th and 6th millennia B.C. It was the first metal used, presumably because it could be found in a native, metallic form which did not require smelting. Its use remained scattered throughout Europe and the Middle East, and the archeological evidence remains scarce. With the invention of smelting, the metallurgic age began and the advantage of combining copper with tin to form bronze was discovered. The earliest bronze artifacts originated from the Middle East and China and date to before 3000 B.C., but it was not until the second millennium B.C. that bronze was used throughout Europe. The ability to smelt and forge iron from about 1000 B.C. marks the end of the Bronze Age and the beginning of the Iron Age.

The oldest recorded medical use of copper is mentioned in the Smith Papyrus, one of the oldest books known (8). This Egyptian medical text, written between 2600 and 2200 B.C., describes the application of copper to sterilize chest wounds and drinking water (8). Greeks, Romans, Aztecs, and others also used copper or copper compounds for the treatment of such ailments as headaches, burns, intestinal worms, and ear infections and for hygiene in general. In the 19th century, a new awareness of copper's medical potency was spawned by the observation that copper workers appeared to be immune to cholera in the 1832 and subsequent outbreaks in Paris, France (8). The use of copper in medicine became widespread in the 19th and early 20th centuries, and a variety of inorganic copper preparations were used to treat chronic adenitis, eczema, impetigo, scrofulosis, tubercular infections, lupus, syphilis, anemia, chorea, and facial neuralgia (8). The use of copper as an antimicrobial agent continued until the advent of commercially available antibiotics in 1932. The spread of antibiotic resistance through selective pressure began and today has made antibiotic-resistant bacteria ubiquitous in hospitals, nursing homes, food processing plants, and animal breeding facilities. This has raised the need for different approaches to keep pathogenic microorganisms at bay. One such alternative is the use of copper surfaces in hygiene-sensitive areas. While this approach is not novel (7), it had lost importance and acceptance in the last few decades. A 1983 report documenting the beneficial effects of using brass and bronze on doorknobs to prevent the spread of microbes in a hospitals remained largely unnoticed (18). Similarly, the idea of using copper vessels to render water drinkable has been revived only very recently as a low-cost alternative for developing countries (37). Currently, there is an intense interest in the use of copper as a self-sanitizing material, and many recent publications deal with mechanistic aspects of “contact killing” (contact-mediated killing) by copper.

COPPER AS A TOXIC BUT ESSENTIAL TRACE ELEMENT

Copper is an essential trace element in most living organisms, and more than 30 types of copper-containing proteins are known today. Prominent examples are lysyl oxidase, which is involved in the cross-linking of collagen, tyrosinase, required for melanin synthesis, dopamine β-hydroxylase, which functions in the catecholamine pathway, cytochrome c oxidase, the terminal electron acceptor of the respiratory chain, and superoxide dismutase, required for defense against oxidative damage. In these enzymes, copper serves as an electron donor/acceptor by alternating between the redox states Cu(I) and Cu(II) (15). Other copper proteins, such as plastocyanins or azurins, act as electron carriers. Depending on the type of coordination of the copper to the protein, the redox potential of copper can vary over the range +200 mV to +800 mV. On the other hand, the redox properties of copper can also cause cellular damage. A number or mechanisms have been suggested. Reactive hydroxyl radicals can be generated in a Fenton-type reaction:

The extremely reactive hydroxyl radical can participate in a number of reactions detrimental to cellular molecules, such as the oxidation of proteins and lipids (45). Copper ions can also lead to depletion of sulfhydryls, such as in cysteines or glutathione, in a cycle between reactions 2 and 3:

The hydrogen peroxide thus generated can in turn participate in reaction 1 and lead to further generation of toxic hydroxyl radicals. It is still not clear to what extent reactions 1 to 3 cause copper toxicity. Cells try to keep H2O2 at very low levels, and reaction 1 may not be the chief toxic mechanism, although this has been frequently claimed. An alternative route of copper ion toxicity has been shown to be the displacement of iron from iron-sulfur clusters (20). Similarly, copper ions may compete with zinc or other metal ions for important binding sites on proteins. The toxic effect of copper on microbes is utilized in agriculture for the control of bacterial and fungal diseases (4), which in fact led to the first thorough investigation of bacterial resistance to copper ions (5).

Bacteria evolved a range of mechanisms to protect themselves from the toxic effects of copper ions: extracellular sequestration of copper ions, relative impermeability of the outer and inner bacterial membranes to copper ions, metallothionein-like copper-scavenging proteins in the cytoplasm and periplasm, and active extrusion of copper from the cell. The latter appears to be the chief mechanism of copper tolerance in bacteria and has been extensively studied in Gram-positive and Gram-negative bacteria. In Escherichia coli, the CopA copper-transporting ATPase resides in the cytoplasmic membrane and pumps excess Cu(I) from the cytoplasm to the periplasm (32). In the periplasmic space, the multicomponent copper efflux system CusCFBA and the multicopper oxidase CueO control the copper level and redox state, respectively. In addition to these chromosomally encoded systems, E. coli strains can harbor related, plasmid-encoded systems which further increase copper tolerance (33). All the components of this copper detoxification machinery are transcriptionally upregulated by copper via two regulatory circuits. In Gram-positive bacteria, which are devoid of a periplasmic space and an outer membrane, only CopA-type copper exporters are present and a single regulatory circuit usually controls their expression (34, 36). A number of other components, like copper-binding proteins, copper reductases, etc., support these basic defense systems against copper and have been described elsewhere (2, 16, 22, 35).

In contrast to copper defense, copper utilization by bacteria is much less well understood. In Synechocystis, it appears that a special copper uptake ATPase serves in supplying copper to the photosynthetic components in the thylakoid membranes (38). On the other hand, methanotrophic bacteria that require copper for particulate methane monooxygenase secrete siderophore-like substances, the methanobactins, to scavenge extracellular copper (2). In Gram-negative bacteria, like E. coli, it is believed that the metalation of cuproenzymes takes place in the periplasmic space and does not require special copper uptake systems across the cytoplasmic membrane. Finally, many novel proteins of unknown function which are regulated by copper have been identified in the Gram-positive organism Lactococcus lactis (21), and further efforts will be required for an in-depth understanding of copper handling by bacteria.

CONTACT KILLING IN THE LABORATORY

The study of the antimicrobial properties of metallic copper surfaces is a relatively recent development and gained momentum when the Environmental Protection Agency (EPA) registered almost 300 different copper surfaces as antimicrobial in 2008 (http://www.epa.gov/pesticides/factsheets/copper-alloy-products.htm). Prior to that, a number of studies have already dealt with the kinetics of contact killing upon exposure of bacteria to copper and copper alloy surfaces (14, 28, 29, 43, 44). Table summarizes the species tested, test procedures, and killing kinetics. In general, microbes were inactivated on copper within hours, but such parameters as the inoculation technique, incubation temperature, and copper content of the alloy used were not usually investigated in a systematic way and are difficult to compare between studies. Nevertheless, a few general principles appear clear: higher copper content of alloys (43), higher temperature (10), and higher relative humidity (25) increased the efficacy of contact killing. Treatments that lowered corrosion rates, e.g., application of corrosion inhibitors or a thick copper oxide layer, lowered the antimicrobial effectiveness of copper surfaces (9).

TABLE 1.

Contact killing of microbes by copper surfaces

| Species |

Application method |

Killing time, RTa

|

Reference |

| Salmonella enterica |

Wet, 4.5 × 106 CFUb

|

4 h |

14 |

| Campylobacter jejuni |

Wet, 4.5 × 106 CFUb

|

8 h |

14 |

|

Escherichia coli O157 |

Wet, (3-4) × 107 CFUc

|

65 min |

43 |

|

Escherichia coli O157 |

Wet, 2.7 × 107 CFUc

|

75 min |

29 |

| MRSAd (NCTC10442) |

Wet, (1-1.9) × 107 CFUc

|

45 min |

28 |

| EMRSA-1e (NCTC11939) |

Wet, (1-1.9) × 107 CFUc

|

60 min |

28 |

| EMRSA-16e (NCTC13143) |

Wet, (1-1.9) × 105 CFUc

|

90 min |

28 |

|

Listeria monocytogenes Scott A |

Wet, 107 CFUc

|

60 min |

44 |

| Mycobacterium tuberculosis |

Wet, 2.5 × 107 CFUf

|

5 to 15 daysg

|

24 |

| Candida albicans |

Wet, >105 CFUf

|

60 min |

24 |

| Klebsiella pneumoniae |

Wet, >107 CFUf

|

60 min |

24 |

| Pseudomonas aeruginosa |

Wet, >107 CFUf

|

180 min |

24 |

| Acinetobacter baumannii |

Wet, >107 CFUf

|

180 min |

24 |

| MRSA |

Wet, >107 CFUf

|

180 min |

24 |

| Influenza A virus (H1N1) |

Wet, 5 × 105 virusesh

|

6 h, 4-log decrease |

30 |

|

C. difficile (ATCC 9689) vegetative cells and spores |

Wet, 2.2 × 105 CFUc

|

24-48 h |

40 |

|

C. difficile NCTC11204/R20291 vegetative cells |

Wet, (1-5) × 106 CFUi

|

30 min |

42 |

|

C. difficile dormant spores |

Wet, 8 × 106 CFUi

|

Unaffected in 3 h |

42 |

|

C. difficile germinating spores |

Wet, 8 × 106 CFUi

|

3 h, 3-log decrease |

42 |

|

Pseudomonas aeruginosa PAO1 |

Wet, 2.2 × 107 CFUj

|

120 min |

10 |

| MRSA NCTC 10442 |

Wet, 2 × 107 CFU |

75 min, 7 log decrease |

25 |

|

Escherichia coli W3110 |

Dry, 109 CFUi

|

1 min |

12 |

|

Acinetobacter johnsonii DSM6963 |

Dry, 109 CFUk

|

A few minutes |

12 |

|

Pantoea stewartii DSM30176 |

Dry, 109 CFUi

|

1 min |

12 |

|

Pseudomonas oleovorans DSM 1045 |

Dry, 109 CFUk

|

1 min |

12 |

|

Staphylococcus warnerii DSM20316 |

Dry, 109 CFUk

|

A few minutes |

12 |

|

Brachybacterium conglomeratum DSM 10241 |

Dry, 109 CFUk

|

A few minutes |

12 |

| Aspergillus flavus |

Wet, (2-300) × 105 sporesc

|

120 h |

41 |

| Aspergillus fumigatus |

Wet, (2-300) × 105 sporesc

|

>120 h |

41 |

| Aspergillus niger |

Wet, (2-300) × 105 sporesc

|

> 576 h |

41 |

| Fusarium culmonium |

Wet, (2-300) × 105 sporesc

|

24 h |

41 |

| Fusarium oxysporum |

Wet, (2-300) × 105 sporesc

|

24 h |

41 |

| Fusarium solani |

Wet, (2-300) × 105 sporesc

|

24 h |

41 |

| Penicillium crysogenum |

Wet, (2-300) × 105 sporesc

|

24 h |

41 |

| Candida albicans |

Wet, (2-300) × 105 sporesc

|

24 h |

41 |

|

Enterococcus hirae ATCC 9790 |

Wet, 107 CFUc

|

90 min |

27 |

| Different Enterococcus spp. |

Wet, 106 CFUf

|

60 min |

39 |

| Candida albicans |

Dry, 106 CFUk

|

5 min |

31 |

| Saccharomyces cerevisiae |

Dry, 106 CFUk

|

30 s |

31 |

In most studies on contact killing, a “wet” inoculation technique was used by applying typically 20 μl of cell suspensions to coupons. While this is a valid approach for laboratory testing, it might not mimic well the dry copper surfaces encountered in health care environments. In an alternative “dry” method, a small volume of liquid is applied to coupons with a cotton swab. The thin film of liquid evaporates within seconds and allows direct contact of all cells with the metal surface. Under these conditions, E. coli and other bacteria were inactivated within a few minutes of exposure (11-13). This suggests that dry metallic copper surfaces are even more antimicrobial than moist ones, which raises interesting questions about the mechanism of contact killing.

Certain Gram-positive bacteria, such as members of the Bacilli and Clostridia, form endospores which can resist heat, radiation, desiccation, denaturing chemicals, etc. Thus, endospores pose a real challenge to aseptic procedures. Clostridium difficile is an important pathogen of the group of spore-forming bacteria and leads to diseases like diarrhea and colitis. Excretion of endospores by infected persons might contaminate surfaces and generate a long-term reservoir for transmission. In spite of the robustness of these spores, killing by metallic copper has been reported in some cases. In one study, viable spores were found to be diminished by 99.8% in 3 h on solid copper (42), while complete inactivation of spores in 24 to 48 h was reported in a second study (40). Clearly, endospores are more resilient to contact killing by copper than vegetative cells, but killing may still occur and thus warrant the strategic use of copper to curb spreading of C. difficile.

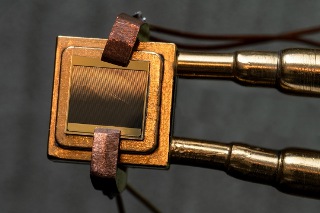

What is the mechanism of contact killing? This question cannot yet be answered clearly, but a number of factors contributing to contact killing have been identified. In wet inoculation of copper surfaces with bacteria, the copper homeostatic systems of the cell appear to play a role. Pseudomonas aeruginosa PAO1 deleted in the cinR gene, encoding a copper-responsive regulator, or the cinA gene, encoding an azurin-like protein involved in copper resistance, was more rapidly killed on copper surfaces than the wild type (10). Similarly, an Enterococcus hirae mutant deleted in the gene for the copper export pump, copB, was killed after 75 min, while complete inactivation of the wild type took 90 min. In E. coli, finally, deletion of three systems, cueO (encoding periplasmic copper oxidase), cus (encoding a periplasmic copper efflux system), and copA (encoding a cytoplasmic copper extrusion pump), led to faster killing kinetics than for the wild type, preincubated with copper to express the copper-homeostatic genes (10, 13). Preincubation with copper also increased the killing time of E. coli carrying the plasmid-borne pco copper resistance system (13). Clearly, bacterial copper resistance systems do not offer protection from contact killing, but they do prolong survival. This suggests the involvement of dissolved copper ions in the killing process (Fig. ). This is further supported by the effect of medium composition on contact killing. Application of the cells to copper surfaces in Tris buffer dramatically enhanced contact killing, and much more copper was dissolved by Tris buffer than by water or phosphate buffer (27). Although spent medium dissolved as much copper as Tris buffer, this copper was probably tightly bound to media components and not bioavailable and thus did not accelerate contact killing. For E. coli, it was shown that copper chelators protected cells from contact killing (13). All these observations support a role of surface-released free copper ions in contact killing, but they are clearly not the sole determinant of the process.

Cartoon of the tentative events in contact killing. (A) Copper dissolves from the copper surface and causes cell damage. (B) The cell membrane ruptures because of copper and other stress phenomena, leading to loss of membrane potential and cytoplasmic content. (C) Copper ions induce the generation of reactive oxygen species, which cause further cell damage. (D) Genomic and plasmid DNA becomes degraded.

Recent studies showed that large amounts of copper ions were taken up by E. coli over 90 min, when cells were applied to copper coupons in a standing drop. When cells were plated on copper by the dry method, the accumulation of copper ions by cells was even more dramatic, reaching a low molar concentration, or 27-fold the level observed by wet plating, in a fraction of the time. The copper ion level of cells remained high throughout the killing phase, suggesting that cells become overwhelmed by their intracellular copper (11). Another factor that influences cell survival on metallic copper is oxidative stress. Generation of reactive oxygen species (ROS) is probably mediated by redox cycling between the different copper species, Cu(0), Cu(I), and Cu(II). The absence of oxygen did not inhibit contact killing of E. coli but doubled the time required for complete killing of 109 cells from 1 to 2 min in the dry plating method (13). This indicates that stress caused by reactive oxygen species is another factor contributing to contact killing.

The fate of DNA during contact killing by copper has also been investigated. According to one study, DNA is a major target of copper toxicity, leading to rapid DNA fragmentation and cell death (39). This contrasts with recent findings by Espirito Santo et al., which suggest that the primary damage to cells in contact killing is membrane damage (11). It is likely that DNA damage ensues only as a secondary event following cell death. It could be shown that membrane damage by copper was not accompanied by an increase in the mutation rate or DNA fragmentation. Deinococcus radiodurans is a bacterium that is exceptionally resistant to ionizing radiation because of its ability to repair even highly fragmented DNA. Remarkably, D. radiodurans was as sensitive as E. coli to contact killing by copper (11). At the current state of knowledge, it appears that contact killing proceeds by successive membrane damage, copper influx into the cells, oxidative damage, cell death, and DNA degradation (cf. Fig. ). Clearly, this sequence of events is still tentative, and further work on contact killing is required to offer more-detailed molecular insight into the process.

How soiling, cleaning, exposure to chemicals, and tarnishing affect the antimicrobial properties of copper has not yet been studied in detail. In a study where copper surfaces were inoculated with bacteria in 1% solutions of albumin, dried, and subsequently cleaned with 70% ethanol or 1% sodium hypochlorite, there was a build-up of residues and a concomitant decrease in killing efficiency (1). On the other hand, it was reported that copper surfaces remained active when soiled (42). Also, it was found that there was no reduction in killing efficiency over 30 cycles of bacterial inoculation, followed by cleaning with a 1% nonionic detergent solution (M. Solioz and C. Molteni, unpublished observations). From what is known about the mechanism of contact killing, it appears clear that a clean copper surface, free of oxide, wax, or other coating agents, will always be active in contact killing. A future task will be to establish reproducible protocols for cleaning copper surfaces such that they maintain maximal efficacy in contact killing.

CONTACT KILLING IN HEALTH CARE SETTINGS

Touch surfaces commonly found in hospitals, such as door handles, touch plates, bed rails, call buttons, toilet seats, etc., can be highly contaminated with microbes. It was shown that germs such as Staphylococcus aureus and Acinetobacter spp. can persist on such surfaces for months (17). Frequent and efficient cleaning, combined with proper hand hygiene, diminishes transmission of infections, but complete elimination appears impossible (6). With the worldwide spread of such antibiotic-resistant organisms as methicillin-resistant S. aureus (MRSA) or more recently New Delhi metallo-beta-lactamase (NDM)-harboring strains, dangerous nosocomial infections have become a primary concern for hospitals. It can be approximated that in 2006 there were about 720,000 hospital-acquired infections in the United States, causing $125 billion in extra hospital charges and more than 74,000 fatalities (database on hospital-acquired infections in Pennsylvania [http://www.phc4.org/]). These numbers emphasize the need for new approaches to hospital hygiene, and antimicrobial copper promises to provide one such approach to supplement the current hygiene measures.

Stainless steel is the metal predominantly used in health care environments because of its “clean” appearance and corrosion resistance. However, there is no inherent antimicrobial advantage to using this metal (19). Copper surfaces, with their self-sanitizing properties, could be envisioned as making an important contribution to infection control. Thus, the use of antimicrobial metallic copper surfaces is likely to provide protection from infectious microbes by reducing surface contamination, as was recently shown in successful hospital trials. Hospital trials are now ongoing worldwide, and the first results have been reported (3, 23, 26).

The 10-week Selly Oak Hospital trial in Birmingham, United Kingdom, was carried out with both copper and control surfaces in the same ward. This approach was chosen to decrease potential bias in the microbial challenge to copper and control surfaces (3). In addition, after 5 weeks, the copper-containing and non-copper-containing surfaces and items were interchanged to further diminish bias. Bacterial contamination of a copper-coated (70% Cu) composite toilet seat, brass tap handles (60% Cu), and a brass door push plate (70% Cu) was compared against that of equivalent items with plastic, chrome-plated, or aluminum surfaces. Median numbers of bacteria recovered from surfaces of copper-containing items were between 90% and 100% lower than those from control surfaces. While MRSA and C. difficile were not isolated in this study, methicillin-sensitive S. aureus (MSSA), vancomycin-resistant Enterococcus (VRE), and E. coli were found only on control surfaces but not on copper surfaces.

It is noteworthy that in contrast to laboratory studies, in which unused copper surfaces are usually tested, this hospital trial employed “aged” surfaces. The items to be tested were installed at least 6 months prior to commencement of the study. This also allowed domestic staff and health care workers to become accustomed to the copper-containing fixtures. In addition, it provides support for the notion that copper surfaces will not lose their antimicrobial activity over time. Nevertheless, long-term studies are still required to evaluate the sustainability of the antimicrobial properties of copper surfaces over the course of several years.

A second hospital trial was contracted at a walk-in primary health care clinic in Grabouw, a rural region of the Western Cape, South Africa (23). Here, a consulting room rather than a medical ward was refitted with copper surfaces. In this room, items in frequent contact with patients and staff, such as desks, trolleys, the top of a cupboard, and windowsills, were covered with copper sheets. During 6 months, surfaces were sampled every 6 weeks for a 4.5-day period, with multiple samplings per day. An overall 71% reduction in the bacterial load of the copper surfaces was observed compared to that of the control surfaces, with significantly lower mean total colony counts during working days and overnight (23). Interestingly, comparable numbers of bacteria were counted when surfaces remained untouched over the weekends (71 h), but this phenomenon was not investigated further.

Finally, in the German trial at the Asklepios Hospital, Hamburg, touch surfaces in patient bed rooms, rest rooms, and staff rooms in an oncological/pneumological and a geriatric ward were refitted with brass (a copper/zinc alloy). Control rooms retained aluminum door handles and push plates and plastic light switches (26). The total duration of this trial was 32 weeks, equally divided into summer and winter months. The number of aerobic, heterotrophic bacteria on these surfaces was determined once or twice per week. The presence of ciprofloxacin-resistant Staphylococcus (CRS) as an indicator organism for multiple-drug-resistant nosocomial pathogens was determined. Following sampling each morning, all surfaces were cleaned with a disinfectant. Additional samples were taken immediately after cleaning and 3, 6, and 9 h later. Over both halves of the trial, there was an average 63% reduction in the bacterial load on copper surfaces compared to controls. Results were significant for door handles, which had the highest overall microbial load. Bacterial numbers recovered from copper and plastic light switches were similar. No significant differences in the survival of CRS on copper and noncopper surfaces were observed, but on average cell numbers from copper were lower. Interestingly, the repopulation of surfaces by microbes occurred at different rates. For copper surfaces, the average rate of repopulation was less than half of that for the control surfaces, documenting the antibacterial properties of copper surfaces.

Results are still awaited from trials at the Memorial Sloan-Kettering Cancer Center in New York City, NY, the Medical University of South Carolina in Charleston, SC, the Ralph H. Johnson VA Medical Center in Charleston, the Hospital del Cobre de Calama in Chile, and the Kitasato University Hospital in Japan. In the hospitals trials described so far, only heterotrophic, aerobic bacteria were assessed. It would be interesting to conduct similar trials in which anaerobic bacteria, including endospore formers and eukaryotic microbes, are also evaluated, since these microbes pose their own unique challenges.

CONCLUSIONS AND FUTURE DIRECTIONS

The antimicrobial properties of copper surfaces have now been firmly established. Hospital trials have shown a reduction in bacterial counts, indicating that copper surfaces are a promising additional tool alongside other hygienic measures to curb the number and severity of hospital-acquired infections. At this point, additional studies would be helpful in determining the most cost-effective way to give maximal protection in hospitals. For example, should only highly frequented sites be made of copper, e.g., doorknobs, faucets, and bed rails, or should the majority of accessible surfaces be made of copper? In addition, different copper alloys should be tested not only for their effectiveness but also for their esthetic appeal. Finally, the antimicrobial properties of copper surfaces must be integrated with other methods of disinfection and the overall hygiene concept of a health care facility. Additional measures, such as the addition of spore germinants to cleaning solutions to improve killing of spores, also deserve further investigation.

Bacterial resistance is a major concern in infection control. Are there bacteria which are naturally refractory to contact killing by copper? It is known that live bacteria can be isolated from copper-containing surfaces, and in a recent study, 294 isolates from European 50-cent coins were investigated in regard to copper resistance. Some of the isolates indeed exhibited prolonged (1 to 3 days) survival on dry but not on moist copper surfaces, but none of the strains was exceptionally copper resistant in culture (12). Survival on copper-containing coins appeared to be the consequence of either endospore formation, survival on patches of dirt, or a special ability to endure a dry metallic copper surface. While the latter, rare property is not yet understood, widespread appearance of bacterial resistant to contact killing appears unlikely for the following reasons: (i) plasmid DNA is completely degraded after cell death by contact killing, preventing the transfer of resistance determinants between organisms (39), (ii) contact killing is very rapid, and cells are not dividing on copper surfaces, precluding the acquisition of resistance, and (iii) copper and copper alloys have been used by humans for thousands of years, yet no bacteria fully resistant to contact killing have been discovered.

ACKNOWLEDGMENTS

Financial support from the Swiss National Foundation (grant 3100A0_122551 to M.S.), pilot NIH grant P20 RR-017675 from the National Center for Research Resources (to G.G.), National Institutes of Health grant GM079192 (to C.R.), grants from the International Copper Association to G.G., C.R., and M.S., and a grant from the Swiss State Secretary for Education & Research (to M.S.) are greatly appreciated. Equipment in the lab of G.G. was purchased with Nebraska Tobacco Settlement Biomedical Research Development Funds.

The contents of this work are solely the responsibility of the authors and do not necessarily represent the official views of the NIH.

BIOGRAPHY

Gregor Grass is Assistant Professor of Microbiology, University of Nebraska—Lincoln. After reunification of his home country, Dr. Grass studied biology at the Martin-Luther Universität Halle-Wittenberg (MLU) in Halle, former East Germany, and completed his Ph.D. in microbiology at MLU with Dietrich H. Nies in 2000 on the highly metal-resistant, ever name-changing bacterium better known as strain CH34. He then worked as a postdoctoral Fellow with Chris Rensing in Tucson, AZ, on metal homeostasis of E. coli. In 2002, he became an independent group leader at MLU, and in 2008, he accepted a position as Assistant Professor at the University of Nebraska—Lincoln. For the last 14 years, Dr. Grass's research interests have centered on the molecular mechanisms of how bacteria acquire essential transition metals from their environments and the cellular systems involved in detoxification of excess trace element cations. Recently, his research focused on the antimicrobial mode of action of metallic copper surfaces.

Gregor Grass is Assistant Professor of Microbiology, University of Nebraska—Lincoln. After reunification of his home country, Dr. Grass studied biology at the Martin-Luther Universität Halle-Wittenberg (MLU) in Halle, former East Germany, and completed his Ph.D. in microbiology at MLU with Dietrich H. Nies in 2000 on the highly metal-resistant, ever name-changing bacterium better known as strain CH34. He then worked as a postdoctoral Fellow with Chris Rensing in Tucson, AZ, on metal homeostasis of E. coli. In 2002, he became an independent group leader at MLU, and in 2008, he accepted a position as Assistant Professor at the University of Nebraska—Lincoln. For the last 14 years, Dr. Grass's research interests have centered on the molecular mechanisms of how bacteria acquire essential transition metals from their environments and the cellular systems involved in detoxification of excess trace element cations. Recently, his research focused on the antimicrobial mode of action of metallic copper surfaces.

Christopher Rensing is Associate Professor of Microbiology, University of Arizona. Dr. Rensing was born in Princeton, NJ, but grew up mainly in Germany. He studied and obtained his Ph.D. at the Freie Universität Berlin and later Martin-Luther Universität Halle-Wittenberg in 1996. His Ph.D. with Dietrich H. Nies sought to gain a better understanding of how Cupriavidus metallidurans CH34 can survive under extremely high concentrations of heavy metals. As a postdoc, he then joined Barry Rosen's lab at Wayne State University in Detroit, MI, working mainly on the biochemical characterization of two metal-transporting P-type ATPases, ZntA and CopA. In 1999 he joined the University of Arizona, and in 2007 he was promoted to Associate Professor. His research is looking at different aspects of metal-microbe interactions, encompassing both environmental and medical microbiology.

Christopher Rensing is Associate Professor of Microbiology, University of Arizona. Dr. Rensing was born in Princeton, NJ, but grew up mainly in Germany. He studied and obtained his Ph.D. at the Freie Universität Berlin and later Martin-Luther Universität Halle-Wittenberg in 1996. His Ph.D. with Dietrich H. Nies sought to gain a better understanding of how Cupriavidus metallidurans CH34 can survive under extremely high concentrations of heavy metals. As a postdoc, he then joined Barry Rosen's lab at Wayne State University in Detroit, MI, working mainly on the biochemical characterization of two metal-transporting P-type ATPases, ZntA and CopA. In 1999 he joined the University of Arizona, and in 2007 he was promoted to Associate Professor. His research is looking at different aspects of metal-microbe interactions, encompassing both environmental and medical microbiology.

Marc Solioz is Professor of Biochemistry, University of Bern. A native of Zurich, Switzerland, Dr. Solioz studied chemistry and engineering in Zurich. He then moved to the United States, where he obtained his Ph.D. in biochemistry at St. Louis University in 1975. The Ph.D. work focused on genetic transfer between photosynthetic bacteria. During postdoctoral studies at the University of Basel with Gottfried Schatz, he investigated the biogenesis of mitochondria and the role of the mitochondrial genome. This was followed by several years as an Assistant/Associate Professor at the Federal Institute of Technology in Zurich (ETH), where he investigated membrane proteins and ion transport by cytochrome oxidases and ATPases. In 1989 he became Professor of Biochemistry at the University of Bern. With the discovery of the first copper-pumping ATPase in 1992, Dr. Solioz's focus shifted to copper, which has remained the subject of his studies to this day.

Marc Solioz is Professor of Biochemistry, University of Bern. A native of Zurich, Switzerland, Dr. Solioz studied chemistry and engineering in Zurich. He then moved to the United States, where he obtained his Ph.D. in biochemistry at St. Louis University in 1975. The Ph.D. work focused on genetic transfer between photosynthetic bacteria. During postdoctoral studies at the University of Basel with Gottfried Schatz, he investigated the biogenesis of mitochondria and the role of the mitochondrial genome. This was followed by several years as an Assistant/Associate Professor at the Federal Institute of Technology in Zurich (ETH), where he investigated membrane proteins and ion transport by cytochrome oxidases and ATPases. In 1989 he became Professor of Biochemistry at the University of Bern. With the discovery of the first copper-pumping ATPase in 1992, Dr. Solioz's focus shifted to copper, which has remained the subject of his studies to this day.

FOOTNOTES

▿Published ahead of print on 30 December 2010.

REFERENCES

1.

Airey, P., and J. Verran. 2007. Potential use of copper as a hygienic surface; problems associated with cumulative soiling and cleaning. J. Hosp. Infect. 67:272-278. [PubMed] [Google Scholar]

2.

Balasubramanian, R., and A. C. Rosenzweig. 2008. Copper methanobactin: a molecule whose time has come. Curr. Opin. Chem. Biol. 12:245-249. [PMC free article] [PubMed] [Google Scholar]

3.

Casey, A. L., et al. 2010. Role of copper in reducing hospital environment contamination. J. Hosp. Infect. 74:72-77. [PubMed] [Google Scholar]

4.

Cha, J. S., and D. A. Cooksey. 1991. Copper resistance in Pseudomonas syringae mediated by periplasmic and outer membrane proteins. Proc. Natl. Acad. Sci. U. S. A. 88:8915-8919. [PMC free article] [PubMed] [Google Scholar]

5.

Cooksey, D. A. 1994. Molecular mechanisms of copper resistance and accumulation in bacteria. FEMS Microbiol. Rev. 14:381-386. [PubMed] [Google Scholar]

6.

Dancer, S. J. 2008. Importance of the environment in meticillin-resistant Staphylococcus aureus acquisition: the case for hospital cleaning. Lancet Infect. Dis. 8:101-113. [PubMed] [Google Scholar]

7. Dick, R. J., J. A. Wray, and H. N. Johnston. 1973. A literature and technology search on the bacteriostatic and sanitizing properties of copper and copper alloy surfaces. Battelle Columbus Laboratories, Columbus, OH.

8.

Dollwet, H. H. A., and J. R. J. Sorenson. 1985. Historic uses of copper compounds in medicine. Trace Elem. Med. 2:80-87. [Google Scholar]

9.

Elguindi, J., et al. Metallic copper corrosion rates, moisture content, and growth medium influence survival of copper-resistant bacteria. Appl. Microbiol. Biotechnol., in press. [PMC free article] [PubMed]

10.

Elguindi, J., J. Wagner, and C. Rensing. 2009. Genes involved in copper resistance influence survival of Pseudomonas aeruginosa on copper surfaces. J. Appl. Microbiol. 106:1448-1455. [PMC free article] [PubMed] [Google Scholar]

11.

Espirito Santo, C., et al. 2011. Bacterial killing by dry metallic copper surfaces. Appl. Environ. Microbiol. 77:794-802. [PMC free article] [PubMed]

12.

Espirito Santo, C., P. V. Morais, and G. Grass. 2010. Isolation and characterization of bacteria resistant to metallic copper surfaces. Appl. Environ. Microbiol. 76:1341-1348. [PMC free article] [PubMed] [Google Scholar]

13.

Espirito Santo, C., N. Taudte, D. H. Nies, and G. Grass. 2008. Contribution of copper ion resistance to survival of Escherichia coli on metallic copper surfaces. Appl. Environ. Microbiol. 74:977-986. [PMC free article] [PubMed] [Google Scholar]

14.

Faundez, G., M. Troncoso, P. Navarrete, and G. Figueroa. 2004. Antimicrobial activity of copper surfaces against suspensions of Salmonella enterica and Campylobacter jejuni. BMC Microbiol. 4:19. [PMC free article] [PubMed] [Google Scholar]

15.

Karlin, K. D. 1993. Metalloenzymes, structural motifs, and inorganic models. Science 261:701-708. [PubMed] [Google Scholar]

16.

Kim, E. H., C. Rensing, and M. M. McEvoy. 2010. Chaperone-mediated copper handling in the periplasm. Nat. Prod. Rep. 27:711-719. [PubMed] [Google Scholar]

17.

Kramer, A., I. Schwebke, and G. Kampf. 2006. How long do nosocomial pathogens persist on inanimate surfaces? A systematic review. BMC Infect. Dis. 6:130-138. [PMC free article] [PubMed] [Google Scholar]

19.

Kusumaningrum, H. D., G. Riboldi, W. C. Hazeleger, and R. R. Beumer. 2003. Survival of foodborne pathogens on stainless steel surfaces and cross-contamination to foods. Int. J. Food Microbiol. 85:227-236. [PubMed] [Google Scholar]

20.

Macomber, L., and J. A. Imlay. 2009. The iron-sulfur clusters of dehydratases are primary intracellular targets of copper toxicity. Proc. Natl. Acad. Sci. U. S. A. 106:8344-8349. [PMC free article] [PubMed] [Google Scholar]

21.

Magnani, D., O. Barré, S. D. Gerber, and M. Solioz. 2008. Characterization of the CopR regulon of Lactococcus lactis IL1403. J. Bacteriol. 190:536-545. [PMC free article] [PubMed] [Google Scholar]

22. Magnani, D., and M. Solioz. 2007. How bacteria handle copper, p. 259-285. In D. H. Nies and S. Silver (ed.), Molecular microbiology of heavy metals. Springer, Heidelberg, Germany.

23.

Marais, F., S. Mehtar, and L. Chalkley. 2010. Antimicrobial efficacy of copper touch surfaces in reducing environmental bioburden in a South African community healthcare facility. J. Hosp. Infect. 74:80-82. [PubMed] [Google Scholar]

24.

Mehtar, S., I. Wiid, and S. D. Todorov. 2008. The antimicrobial activity of copper and copper alloys against nosocomial pathogens and Mycobacterium tuberculosis isolated from healthcare facilities in the Western Cape: an in-vitro study. J. Hosp. Infect. 68:45-51. [PubMed] [Google Scholar]

25.

Michels, H. T., J. O. Noyce, and C. W. Keevil. 2009. Effects of temperature and humidity on the efficacy of methicillin-resistant Staphylococcus aureus challenged antimicrobial materials containing silver and copper. Lett. Appl. Microbiol. 49:191-195. [PMC free article] [PubMed] [Google Scholar]

26.

Mikolay, A., et al. 2010. Survival of bacteria on metallic copper surfaces in a hospital trial. Appl. Microbiol. Biotechnol. 87:1875-1879. [PubMed] [Google Scholar]

27.

Molteni, C., H. K. Abicht, and M. Solioz. 2010. Killing of bacteria by copper surfaces involves dissolved copper. Appl. Environ. Microbiol. 76:4099-4101. [PMC free article] [PubMed] [Google Scholar]

28.

Noyce, J. O., H. Michels, and C. W. Keevil. 2006. Potential use of copper surfaces to reduce survival of epidemic meticillin-resistant Staphylococcus aureus in the healthcare environment. J. Hosp. Infect. 63:289-297. [PubMed] [Google Scholar]

29.

Noyce, J. O., H. Michels, and C. W. Keevil. 2006. Use of copper cast alloys to control Escherichia coli O157 cross-contamination during food processing. Appl. Environ. Microbiol. 72:4239-4244. [PMC free article] [PubMed] [Google Scholar]

30.

Noyce, J. O., H. Michels, and C. W. Keevil. 2007. Inactivation of influenza A virus on copper versus stainless steel surfaces. Appl. Environ. Microbiol. 73:2748-2750. [PMC free article] [PubMed] [Google Scholar]

31.

Quaranta, D., et al. 2011. Mechanisms of contact-mediated killing of yeast cells on dry metallic copper surfaces. Appl. Environ. Microbiol. 77:416-426. [PMC free article] [PubMed] [Google Scholar]

32.

Rensing, C., and G. Grass. 2003. Escherichia coli mechanisms of copper homeostasis in a changing environment. FEMS Microbiol. Rev. 27:197-213. [PubMed] [Google Scholar]

33.

Rouch, D., J. Camakaris, B. T. Lee, and R. K. Luke. 1985. Inducible plasmid-mediated copper resistance in Escherichia coli. J. Gen. Microbiol. 131:939-943. [PubMed] [Google Scholar]

34.

Solioz, M., H. K. Abicht, M. Mermod, and S. Mancini. 2010. Response of Gram-positive bacteria to copper stress. J. Biol. Inorg. Chem. 15:3-14. [PubMed] [Google Scholar]

35. Solioz, M., S. Mancini, H. K. Abicht, and M. Mermod. The lactic acid bacteria response to metal stress. In K. Papadimitriou and E. Tsakalidou (ed.), Stress response of lactic acid bacteria, in press. Springer, Heidelberg, Germany.

36.

Solioz, M., and J. V. Stoyanov. 2003. Copper homeostasis in Enterococcus hirae. FEMS Microbiol. Rev. 27:183-195. [PubMed] [Google Scholar]

37.

Sudha, V. B. P., K. O. Singh, S. R. Prasad, and P. Venkatasubramanian. 2009. Killing of enteric bacteria in drinking water by a copper device for use in the home: laboratory evidence. Transact. R. Soc. Trop. Med. Hyg. 103:819-822. [PubMed] [Google Scholar]

38.

Tottey, S., P. R. Rich, S. A. Rondet, and N. J. Robinson. 2001. Two Menkes-type ATPases supply copper for photosynthesis in Synechocystis PCC 6803. J. Biol. Chem. 276:19999-20004. [PubMed] [Google Scholar]

39.

Warnes, S. L., S. M. Green, H. T. Michels, and C. W. Keevil. 2010. Biocidal efficacy of copper alloys against pathogenic enterococci involves degradation of genomic and plasmid DNA. Appl. Environ. Microbiol. 76:5390-5401. [PMC free article] [PubMed] [Google Scholar]

40.

Weaver, L., H. T. Michels, and C. W. Keevil. 2008. Survival of Clostridium difficile on copper and steel: futuristic options for hospital hygiene. J. Hosp. Infect. 68:145-151. [PubMed] [Google Scholar]

41.

Weaver, L., H. T. Michels, and C. W. Keevil. 2010. Potential for preventing spread of fungi in air-conditioning systems constructed using copper instead of aluminium. Lett. Appl. Microbiol. 50:18-23. [PubMed] [Google Scholar]

42.

Wheeldon, L. J., et al. 2008. Antimicrobial efficacy of copper surfaces against spores and vegetative cells of Clostridium difficile: the germination theory. J. Antimicrob. Chemother. 62:522-525. [PubMed] [Google Scholar]

43.

Wilks, S. A., H. Michels, and C. W. Keevil. 2005. The survival of Escherichia coli O157 on a range of metal surfaces. Int. J. Food Microbiol. 105:445-454. [PubMed] [Google Scholar]

44.

Wilks, S. A., H. T. Michels, and C. W. Keevil. 2006. Survival of Listeria monocytogenes Scott A on metal surfaces: implications for cross-contamination. Int. J. Food Microbiol. 111:93-98. [PubMed] [Google Scholar]

45.

Yoshida, Y., S. Furuta, and E. Niki. 1993. Effects of metal chelating agents on the oxidation of lipids induced by copper and iron. Biochim. Biophys. Acta 1210:81-88. [PubMed] [Google Scholar]

Gregor Grass

Gregor Grass Christopher Rensing

Christopher Rensing Marc Solioz

Marc Solioz